A Review of Lime Mortar Sand

Lime mortars gain most of their structural strength and longevity from the sand. Sand must be sharp and able to pack firmly and tightly together. The lime in a true lime mortar only acts as a binder to hold sand in a packed interlocked state. The binder does not actually contribute structurally other than to hold the sand in place. Sand must have a wide variety of particle sizes, be sharp, angular and structurally interlock tightly of its own accord.

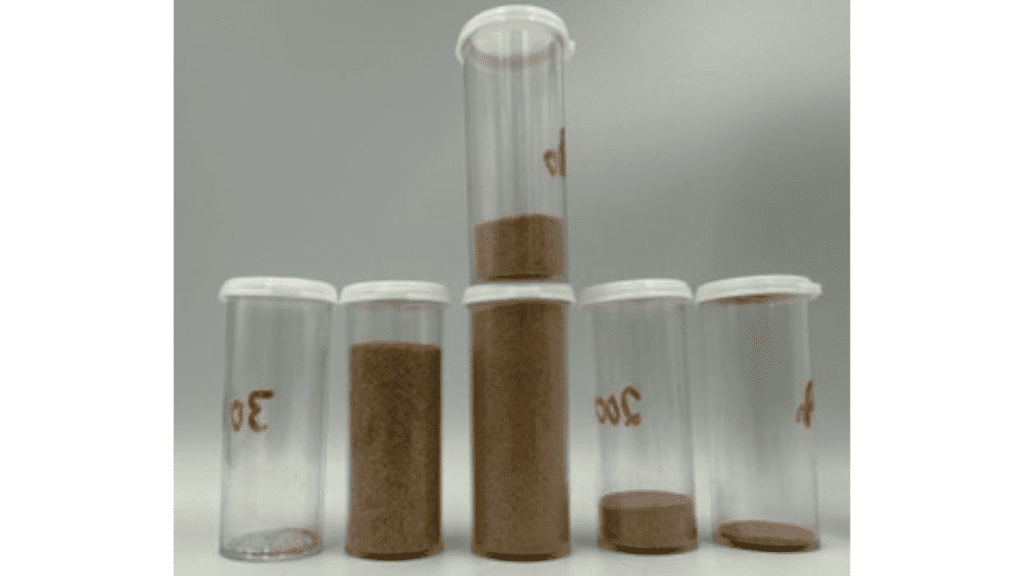

We describe this wide variety of particle sizes as a “bell curve”. Sieve the sand, place it in vials and line them up and the bell curve appears. Place the vials in a row according to the weight retained in each sieve. The height of sand in the vials will resemble the shape of a bell. A small quantity of sand is in the vials of larger particles, a larger amount of sand is in the center vials and a lesser amount of sand is in the vials of small particles. (See above photo)

A good bell curve of sharp and angular sand indicates a sand that packs firmly and tightly. Lack of a distinct visual bell curve indicates a lime mortar that is structurally weak. It will not compact tightly and will have early failure.

How Gravel Driveways function

An example that describes the importance of a wide variety of sand particles is to study gravel for driveways. A ¾” clean stone used on a driveway will never compact. Compact it, or drive over it, and it will always be loose. This is because a ¾” clean stone mix contains stone particles of basically all the same size. The correct stone mix for a driveway in this area of Pennsylvania as an A1-Modified Stone. It is a stone mix that has a wide variety of sizes including plenty of stone dust. This mix will compact firmly and create a structurally hard surface for vehicles.

Sand Designations

Most naturally occurring creek and river sands have a wide variety of particles sizes for the needed bell curve. The closest manufactured sand that has the proper bell curve is often called a concrete sand. It is given the designation ASTM C33 (although most ASTM C33 sands are lacking the necessary fines). An ASTM C33 sand will have very poor workability when mixed with Portland cement masonry mortars, but when mixed with the proper ratio with lime will have beautiful workability.

ASTM C144 is a commonly available sand in the USA. This sand is designed and manufactured for use in Portland Cement mortars to give them increased workability. However, the ASTM C144 basically has two particle sizes in it. Sieve 50 and sieve 100 contain the majority of the aggregate. Because of the limited particle sizes in this sand, it will never compact well. Portland Cement provides most of the strength in a Portland mortar. Therefore the structural packing ability of sand for Portland cement is not a major focus.

Sieve Analysis

It is important to keep in mind that ASTM C33 and ASTM C144 standards do allow a large leeway on the exact particle size and distribution allowed. Sieve and examine the sand, before using in a lime mortar. If the sieve results are not ideal, add the missing particles into the mix.

It is crucial when reading a sieve analysis chart or looking at the sand in vials to realize that a smooth and evenly weighted particle size distribution on both halves of the bell curve is best. The mid sieve amounts should be the highest in percentage in comparison to the upper and lower sieve amounts. If the fineness modulus number indicates “fail”, but the sand has an acceptable curve, we will deem that the sand is acceptable because the strength of the packing will be good. If the fineness modulus “passes”, but the bell curve is abnormal, the packing of the mortar will be poor. Keep in mind that it is rare to find a perfect bell curve of sand in a naturally occurring sand. Avoid Sands that have “spikes” between the sieves. Adjust the sand to achieve an even bell curve.

Concluding Sand Thoughts

Lancaster Lime Works does not find it overly important to identify the geological “types” of aggregate that are within the sample. Rather, we determine whether the aggregate is sharp, angular and has the appropriate bell curve for use in a lime mortar. We look for sand that mostly consists of silica and quartz particles. Avoid sand that has greater than 25% of stone particles, especially softer stone such as limestone or brownstone etc. Often the key to finding aggregate to match original aggregate is to look on the building site.

Once a sand with a correct bell curve and particle shape is found, it is very important to perform a void analysis in order to calculate the lime to sand ratio for that particular sand. The lime to sand ratio is not discussed in this paper.

The study of sand needed for lime mortar is vast. We have condensed the basics in this study. As with so many aspects of the historic restoration field, there is great danger of a little knowledge. Reliance of standard ASTM specifications is usually not good enough. The specifier must be involved in the actual work. They must be very familiar with how the materials used are contributing to the mix in order to ensure that things turn out well. Empirical development of a lime replacement mortar formula may produce a mixture that “sounds wrong” to specifiers but will be structurally correct, strong, durable and historically correct.

You must be logged in to post a comment.